In-Line Ultra Sanitary Mixers

In-Line Ultra Sanitary Mixers

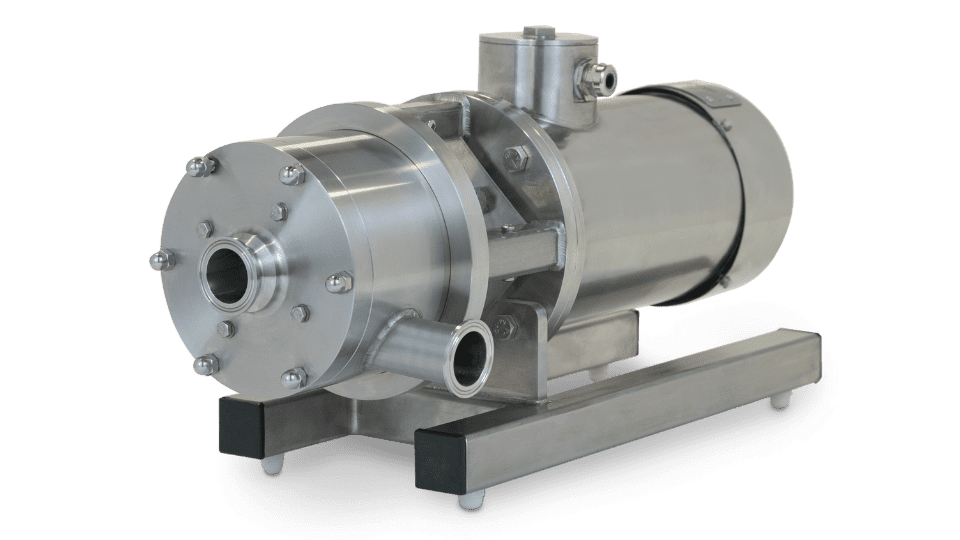

The Silverson Ultra Sanitary series of multipurpose In-Line mixers are able to perform the widest variety of applications - mixing, emulsifiying, homogenizing, disintegrating and dissolving, with an efficiency, flexibility and sanitary construction unmatched by other machines. UHS range mixers are 3-A TPV (Third Party Verification) Certified and are fitted with EHEDG Certified Mechanical Shaft Seals, fully EHEDG-certified models are available. They are designed to comply with both FDA and cGMP guidelines.

Features:

- Self-pumping

- Aeration free

- No bypassing

- Interchangeable workheads

- Self-draining tangential outlet

- Ultra Sanitary single mechanical shaft seals, easily converted to double mechanical shaft seals

- No manual dismantling and cleaning is required, significantly reducing maintenance, operating cost, increasing reliability and increasing productivity

How It Works

Silverson's line of high shear In-Line mixers offers a great many advantages to the processor - speed, versatility, self-pumping, aeration-free, guaranteed efficiency. At the heart of every mixer is Silverson's high performance rotor/stator workhead.

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly.

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.

-

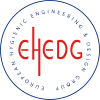

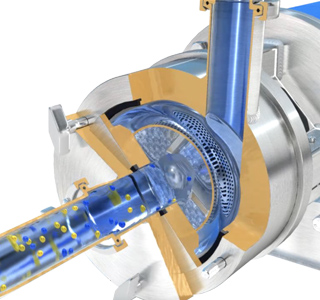

Stage 1

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly.

-

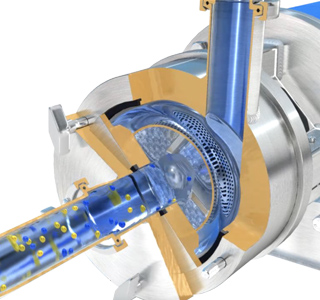

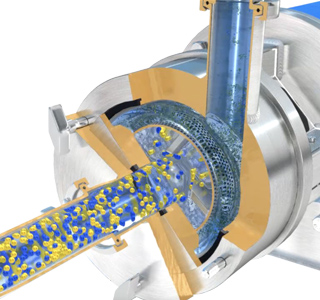

Stage 2

Stage 2

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

-

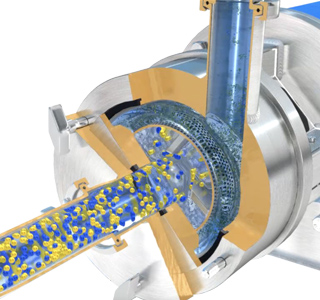

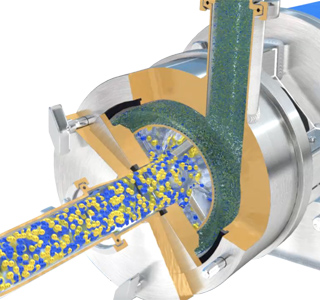

Stage 3

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.

Videos

In-Line Ultra Sanitary mixers

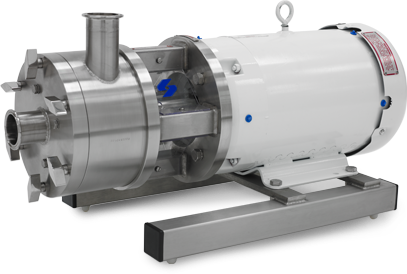

Verso UHS Ultra Sanitary Mixer

Mixer Options

Workheads

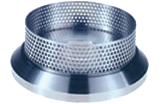

A comprehensive range of workheads and screens is available for all Silverson high shear mixers. These easily interchangeable workheads offer great versatility by allowing any machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenizing, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. Changing from one head or screen to another is quick and simple.

Technical Information

- Capacity

- Self-pumping throughputs of 5 to 25,000 gallons/hr.

- No Bypassing

- Product cannot bypass the precision rotor/stator workhead.

- Interchangeable Workheads

- Single stage rotor/stator configurations as standard. For those applications that require greater shear, interchangeable multistage configurations can be used.

- Materials of Construction

- Product contact parts in 316L stainless steel. Special materials available on request.

- Inlet and Outlet Connections

- All sanitary or flange fittings available upon request (i.e. Tri-Clamp, ASA, DIN, etc). All Silverson In-Line Mixers are designed for cleaning-in-place (CIP and SIP).

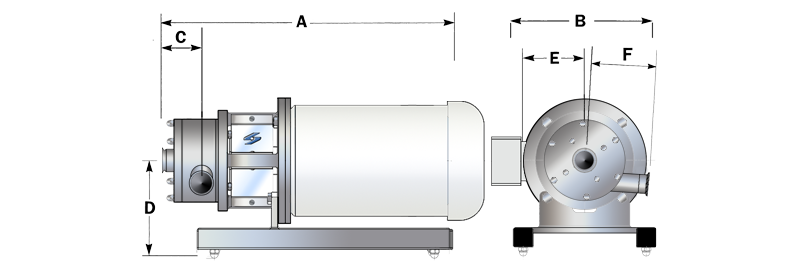

UHS In-line Mixers, tri-clamp, 60Hz Motors - Dimensions in Inches

| HP | RPM | TEFC A | EXPL A | B | C | D | E | F | Inlet/ Outlet |

|

|---|---|---|---|---|---|---|---|---|---|---|

| 275 | 2 | 3600 | 20 | 19 ⅞ | 8 ½ | 3 ⅛ | 6 ½ | 6 ⅝ | 5 ¼ | 1 ½ |

| 425 | 7 ½ | 3600 | 26 ³⁄16 | 26 ⁹⁄16 | 11 13/16 | 3 11/16 | 6 ⁷⁄16 | 8 ⅞ | 7 ⅛ | 2 |

| 450 | 10 | 3600 | 26 ³⁄16 | 26 ⁹⁄16 | 11 13/16 | 3 11/16 | 6 ⁷⁄16 | 8 ⅞ | 7 ⅛ | 2 |

| 600 | 30 | 3600 | 35 ⅝ | 35 ⅝ | 15 | 4 ⁵⁄16 | 7 ¾ | 11 ⅛ | 8 ¼ | 3 |

The dimensions shown are approximate only and certified diagrams should be used for installation purposes.

Silverson reserves the right to change dimensions and specifications without notice.