Sanitary Mixers

Sanitary Mixers

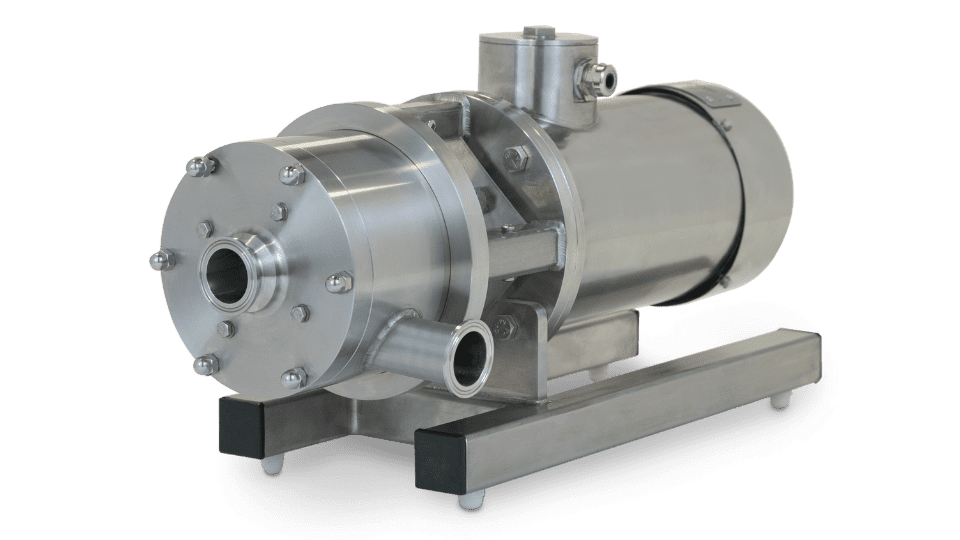

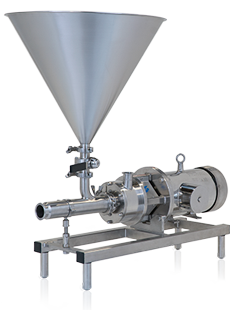

In industries where product purity and hygiene are paramount, maintaining sanitary conditions in mixing processes is of the utmost importance. Silverson understands this critical need and offers a range of sanitary mixers designed to meet the highest standards of cleanliness and hygiene.

Sanitary Mixing at Any Scale

Silverson Machines has a comprehensive product line of high-performance mixers from Laboratory scale mixers for amounts as small as 1ml up to full scale product mixers capable of handling batches of up to 30,000 liters. Many of the machines in the product line can be supplied in sanitary and “Ultra-sanitary” specifications.

Silverson standard mixers offer a high level of hygienic construction and for more advanced requirements, Silverson has been a pioneer in the design and manufacture of a new generation of “Ultra Sanitary” mixing equipment specifically aimed at stringent applications.

This range of Ultra Sanitary are ideally suited for industries where cleaning-in-place (CIP) and sterilizing-in-place (SIP) procedures are the norm. Not only do these include the food, pharmaceutical and cosmetic industries, but also more diverse applications where modern manufacturing techniques and maximum equipment utilization require a rapid changeover from one product to another.

Case Study: Pharmaceutical Syrup Production at Ambient Temp

Key Features and Benefits

Silverson Sanitary mixers offer:

- Compliance

Our mixers meet regulatory standards and industry requirements for sanitary mixing, providing peace of mind to manufacturers and consumers alike. Silverson’s range of Sanitary mixers are 3-A TPV (Third Party Verification) Certified, EHEDG Certifiable and designed to comply with FDA, USDA and cGMP requirements. - Hygienic Construction

Stainless steel, crevice-free, electro-polished finish provides easy cleaning, corrosion resistance, and durability. - Sanitary Seals and Fittings

Prevents product contamination and ensures hygienic operation. - High Shear Mixing Technology

Enables efficient and uniform blending of ingredients, enhancing product quality. - Reduced Processing Times

Silverson mixers offer faster mixing cycles, leading to increased productivity.

Find Your Application

Silverson sanitary mixers are used in applications across various industries, including pharmaceutical manufacturing, cosmetic formulation, and food processing. Whether it’s tablet coating, ointment production, emulsion blending, or sauce manufacturing, our mixers deliver consistent and reliable performance, ensuring product integrity and quality.

View our mixing application guides and how-to videos here:

Customization and Support

We understand that every manufacturing process is unique, which is why we offer tailored solutions to meet specific customer requirements and applications. Our technical support team provides comprehensive assistance, including installation guidance and training to ensure optimal performance and longevity of Silverson mixers.

Silverson can also assist in the preparation of Installation Qualification/Operational Qualification protocols for process equipment (IQ/OQs) and other documentation packages including data dossiers for FDA and other regulatory body validation.

Why Choose Silverson?

- Experience: Over 75 years of helping thousands of companies in diverse industries has given us the in-depth knowledge necessary to develop mixing solutions that deliver the results you need.

- Reliability: Our mixers are known for their high performance and durability, delivering consistent results batch after batch.

- Innovation: We continuously innovate to provide cutting-edge solutions that meet evolving customer needs and industry trends.

- Customer Satisfaction: Silverson is committed to customer satisfaction, offering superior products and support to help manufacturers achieve their production goals.

Elevate your mixing processes to new levels of efficiency, hygiene, and productivity with Silverson’s range of sanitary mixers. Reach out below to arrange a trial or consult our team of experts about your specific mixing needs.